- Tel: 0086-15163060906

- Email: wellyfull@163.com

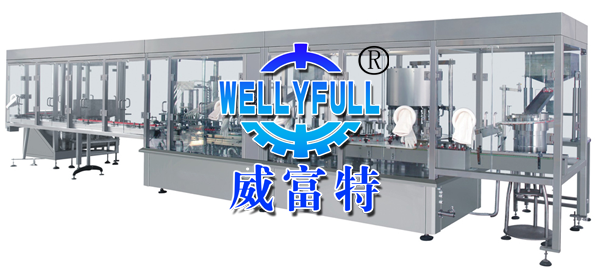

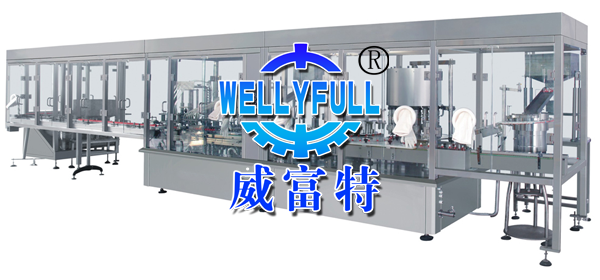

GPR-D Series Eyedrop Flat & Round bottles Automatic Unscrambler, Bottles Rinser, Drying & Stoppering & Capping, Light Inspection, Labeling Production Line (Appliance For Eye Drop, Nose & Ear Drop, Contact Lens Nursing Liquid)

Description:

This Line Ensemble is produced by imported advanced technology that integrates mechanics, electronics, and pneumatics into an organic whole of technology. It is a newly developed Ophthalmic Lotion Filling Line taking the leading place.The Line,being an initiative in our country,consists of GHR-AC Automatic Bottle unscrambler unit, GHR-B Rolling bottle rinser Unit (two processed by water cleaning and one by compressed air), GHR-C Ozone sterilization stoving Trunk, GHR-A accumulator, GHR-D eyedrop Liquid Filling Unit (with stopper inserting and capping mechanism), GHR-DN Light inspection unit and GHR-EA vertical Labeling Unit. The equipment has won great reputation form numerous customers home and abroad for its high automation, high speed, universal adaptability and excellent stability. This Line Ensemble can complete automatically and successively different tasks such as bottle orienting, water/air cleaning, preliminary air drying, Ozone sterilization stoving,liquid filling, stopper inserting, capping, light inspection, label sticking and batch number marking. The Line filled up blanks in the manufacturing of the similar equipments in our country and has abvious got superiority over similar products home and abroad, indicating the strength of our company in designing and manufacturing such equipment. The Line can perfectly meet GMP Regulations for pharmaceutical production. It can also perfectly take place of any imported equipment.

Main Technical Parameter:

Appliance for bottle: eyedrop bottle and other similar bottles

Appliance for the bottles:2-25ml (more larger dosage can be customized)

Production capacity:40-60bpm (single fill nozzles) 80-120bpm (double fill nozzles)

Tolerance of filling quantity: ≤±1% standard

Yield of bottle orienting: ≥98%

Yield of capping : ≥98%

Air pressure: 4-6kg/cm2

Water pressure: 3-4kg/cm2

Air consumption: 30m3/h

Water consumption: 0.6m3/h

Total output: ≤5Kw

Power source: 380/220V 50/60Hz